In industries such as pharmaceuticals, food, and personal care, packaging is more than just a container — it’s a protective barrier that safeguards product quality and consumer safety. However, even the smallest undetected leak can lead to contamination, reduced shelf life, or product recalls. This is why package leak test equipment has become a vital component in modern production lines, ensuring the integrity and reliability of every sealed product that leaves the factory.

Why Leak Detection Matters

For manufacturers, packaging integrity directly affects product performance and brand reputation. A single compromised seal could allow moisture, air, or microorganisms to enter, which can alter product stability or render it unsafe for consumption.

In regulated industries like pharmaceuticals and medical devices, leak detection is also a compliance requirement under GMP and ISO standards. Automated package leak test equipment provides a non-destructive, repeatable, and highly accurate solution for verifying packaging integrity — ensuring every batch meets both safety and regulatory standards.

How Package Leak Test Equipment Works

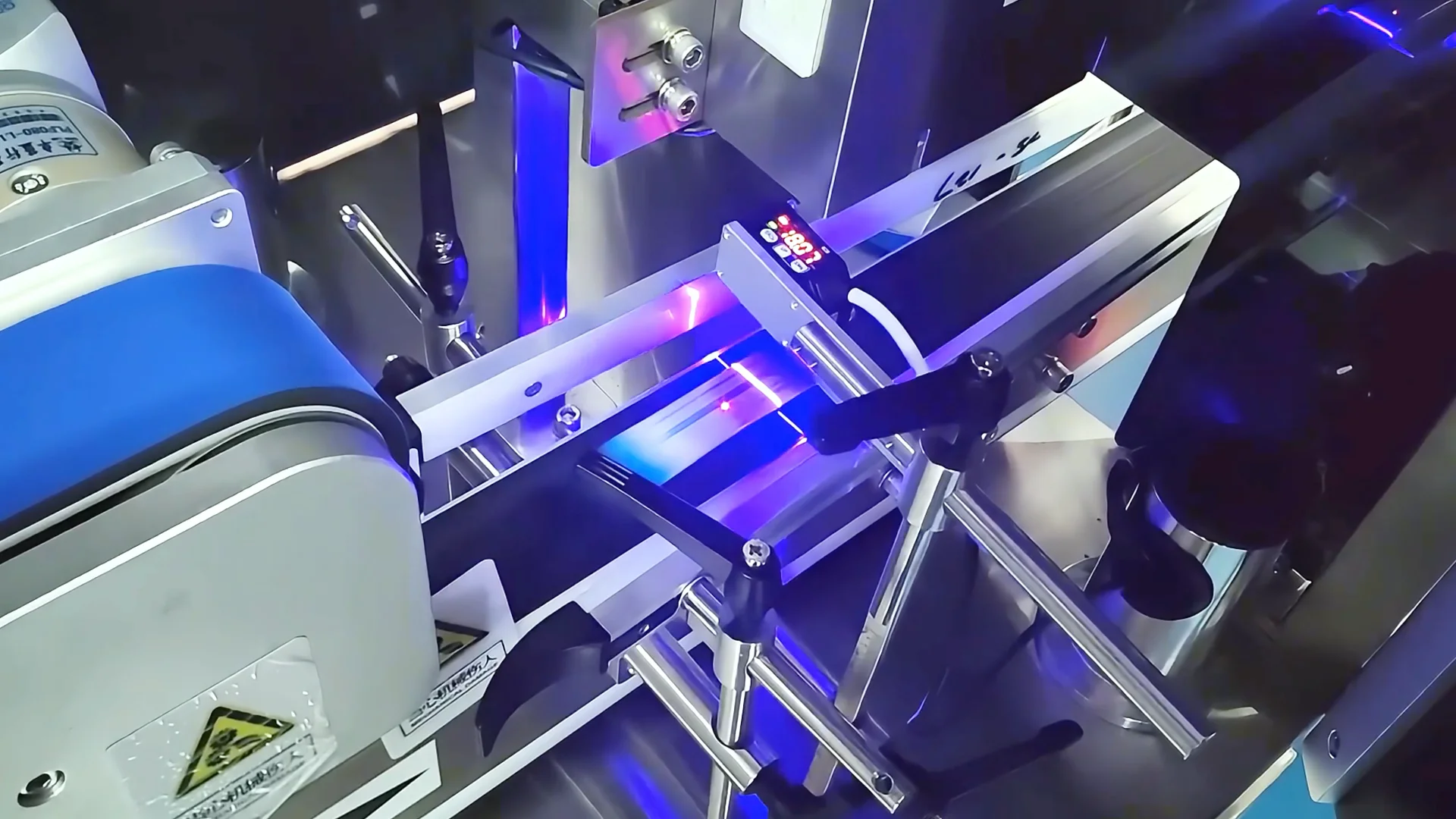

Modern leak testing systems use various detection principles depending on the packaging type, including vacuum decay, pressure differential, and high-voltage discharge methods.

For instance:

-

Vacuum and pressure decay systems detect pressure changes that indicate air leakage in flexible pouches or blister packs.

-

High-voltage discharge systems, such as those used in BFS micropore leak inspection technology, apply a controlled electrical field across non-conductive packaging. When a microscopic hole or crack exists, a discharge current occurs, identifying leaks as small as a few micrometres — without damaging the product.

Another widely used application is stick pack and sachet leak inspection, where air-tight seals are critical for powders, liquids, or gels. Systems like the stick pack and sachet leak inspection machine combine pressure decay detection with automated sorting, ensuring rapid, non-destructive testing even at high production speeds.

Key Benefits for Manufacturing Enterprises

1. Enhanced Product Safety

Leak testing ensures that packaging performs its protective function, reducing the risk of contamination and maintaining product sterility.

2. Compliance with International Standards

Automated systems help manufacturers meet regulatory requirements, including USP 1207, EU GMP Annex 1, and ISO 11607, through validated and traceable test data.

3. Increased Production Efficiency

Non-destructive inspection allows continuous testing without sacrificing product units. Modern systems can handle hundreds of packages per minute, supporting mass production environments.

4. Cost Reduction and Waste Minimization

By detecting defects early, manufacturers prevent downstream losses from rework, scrap, or recall, improving operational efficiency and cost control.

5. Flexibility Across Packaging Types

Advanced leak test equipment can adapt to multiple formats — from BFS containers and ampoules to pouches and sachets — offering scalability across different product lines.

Emerging Trends in Leak Detection Technology

As Industry 4.0 continues to evolve, leak detection is shifting from offline sampling to real-time, inline inspection. Integration with vision systems, AI-driven defect analysis, and data traceability platforms allows manufacturers to monitor seal integrity continuously and trace every batch digitally.

Additionally, sustainability goals are reshaping how packaging is designed and tested. Leak testing systems are being optimized to handle thinner, recyclable materials without compromising detection sensitivity — aligning product safety with environmental responsibility.

Conclusion

In modern manufacturing, package leak test equipment is not just a quality control tool — it’s a strategic investment in brand protection and operational excellence. Whether testing BFS ampoules, stick packs, or medical pouches, leak detection ensures that every product leaving the line meets the highest standards of safety and reliability.

By adopting advanced technologies like high-voltage discharge and non-destructive pressure decay, enterprises can secure product integrity, streamline compliance, and strengthen customer confidence in their packaging systems.