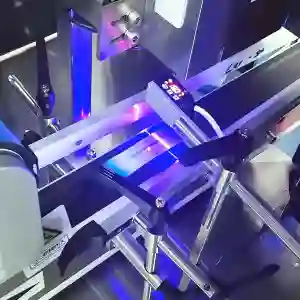

In modern electronic manufacturing, precision is no longer a competitive advantage—it is a baseline requirement. As product designs become thinner, more compact, and more complex, the accuracy of adhesive application on backplanes plays a decisive role in structural integrity, thermal performance, and long-term reliability. This is where the Backplane glue coating machine becomes a mission-critical piece of production equipment.

Designed for speed, stability, and full automation, the latest generation of backplane glue coating machines enables manufacturers to meet high-throughput demands while maintaining micron-level consistency.

Why Backplane Glue Coating Requires Dedicated Automation

Backplanes are foundational structural and functional elements in products such as displays, control panels, power modules, and industrial electronics. Adhesive coating on backplanes must meet several stringent requirements simultaneously:

-

Uniform glue thickness across large surface areas

-

Precise positioning relative to component geometry

-

High repeatability across production batches

-

Compatibility with different backplane sizes and layouts

Manual or semi-automatic coating methods introduce variability, slow down production, and increase defect risk. A fully automated Backplane glue coating machine eliminates these issues by integrating mechanical positioning, rigid structural design, and intelligent control systems.

Core Design Philosophy of the Backplane Glue Coating Machine

Compatibility with Standard Component Dimensions

The glue coating machine is engineered to meet the general length and width specifications of backplane components, ensuring broad applicability across multiple product lines. This flexibility allows manufacturers to standardize equipment without sacrificing adaptability.

Mechanical Lead Positioning for Absolute Accuracy

The lead positioning method relies on mechanical positioning, not visual estimation or manual alignment. This approach delivers:

-

Consistent reference points

-

High repeatability regardless of operator skill

-

Stable positioning even at high operating speeds

Mechanical positioning is particularly valuable in environments where vibration, temperature variation, or long operating cycles could affect accuracy.

Steel Main Frame for Industrial Reliability

The main frame structure is fabricated from steel, providing a rigid and durable foundation for high-speed adhesive operations. Compared to lightweight frames, a steel structure offers:

-

Reduced vibration during rapid movement

-

Long-term dimensional stability

-

Higher load-bearing capacity

This structural integrity directly contributes to coating precision and machine lifespan, making the equipment suitable for continuous industrial operation.

Speed, Accuracy, and Stability in One System

One of the defining advantages of a modern Backplane glue coating machine is its ability to combine speed with precision—two parameters that often conflict in traditional systems.

Key performance characteristics include:

-

Fast operation cycles to support high-volume production

-

High positioning accuracy for precise glue paths

-

Stable motion control for uniform coating results

-

Reliable performance over extended production runs

This balance ensures that increased throughput does not come at the expense of product quality.

Intelligent Automation for Consistent Output

The equipment operates under fully automatic control, requiring no human intervention during the coating process. Once parameters are configured, the machine executes the entire sequence autonomously.

This automation delivers measurable benefits:

-

Reduced labor dependency

-

Elimination of operator-induced variability

-

Predictable and repeatable coating quality

-

Improved production safety

For manufacturers pursuing smart factory or Industry 4.0 initiatives, such automation is not optional—it is foundational.

One-Click Version Switching and Program Recall

Production environments often require frequent changes in backplane design or coating patterns. The machine addresses this with one-click version switching and correction, allowing operators to:

-

Instantly change coating programs

-

Recall pre-stored parameters directly

-

Minimize setup and adjustment time

This feature dramatically reduces downtime between batches and supports flexible, multi-model production strategies.

Application Scenarios Across Industries

The Backplane glue coating machine is widely applicable in sectors that demand precision adhesive application, including:

-

Consumer electronics manufacturing

-

Industrial control systems

-

Display and panel assembly

-

Power electronics and energy equipment

Its adaptability to different backplane sizes and adhesive requirements makes it a versatile asset in both mass production and customized manufacturing environments.

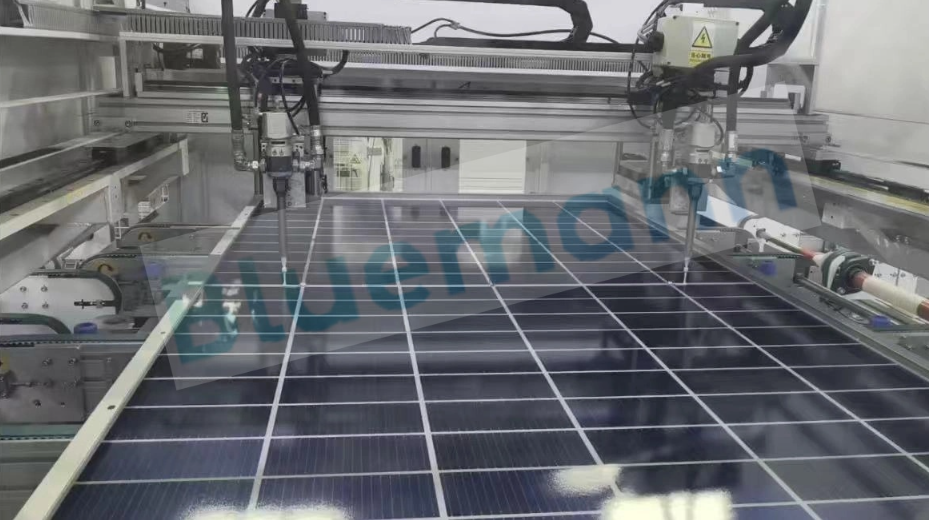

Bluemann: Engineering Automation with Industrial Insight

As a specialist in intelligent manufacturing equipment, Bluemann focuses on delivering automation solutions that balance engineering rigor with real-world production needs. The company’s backplane glue coating machines reflect a deep understanding of:

-

Industrial adhesive behavior

-

Mechanical motion control

-

Automation reliability and scalability

Bluemann emphasizes robust design, user-friendly operation, and long-term stability—qualities that resonate strongly with manufacturers seeking dependable automation partners rather than short-term solutions.

Operational Value Beyond the Machine Itself

Investing in a high-performance Backplane glue coating machine yields benefits that extend beyond immediate production metrics:

-

Lower defect and rework rates

-

Reduced material waste

-

Improved product consistency

-

Faster response to design changes

Over time, these advantages translate into improved profitability, stronger quality control, and enhanced competitiveness in demanding markets.

Conclusion: Automation That Delivers Measurable Precision

In a manufacturing landscape defined by speed, accuracy, and flexibility, the Backplane glue coating machine stands out as a cornerstone of efficient backplane assembly. Through mechanical positioning, steel-frame stability, full automation, and intelligent program management, it addresses the real challenges of modern production.

With its engineering-focused approach and commitment to reliability, Bluemann provides manufacturers with a solution that is not only technically advanced but also commercially practical—supporting scalable growth without compromising quality.