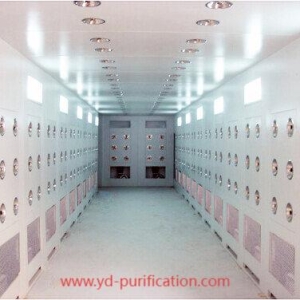

In advanced manufacturing and laboratory settings, maintaining a controlled environment is essential. The Clean Room Door by YD-Purification ensures that sterile conditions remain uncompromised while allowing smooth operations. Are you confident that your current facility meets the highest standards of hygiene and air control?

Modern clean rooms require doors that are more than simple entryways. They must provide airtight seals, durable construction, and resistance to frequent usage. High-quality materials and precision engineering allow doors to withstand rigorous industrial demands without sacrificing safety or aesthetic appeal.

Hygiene plays a critical role in clean room design. Doors often serve as the first line of defense against contamination. Utilizing advanced sealing technology, anti-bacterial surfaces, and smooth finishes, these installations minimize particulate intrusion, contributing to reliable results in sensitive environments. Such meticulous design supports industries ranging from pharmaceuticals to electronics, where even minor contamination can disrupt processes or compromise product integrity.

Functionality is equally vital. Beyond basic entry and exit, doors can offer automated opening, integrated access control, and soundproofing to reduce distractions in high-concentration areas. Ergonomic designs ensure that operators can navigate them effortlessly while maintaining a sterile environment. Safety measures, including fire-resistant frames and tempered glass panels, provide additional assurance for personnel and property.

Customization is a key aspect. Facilities vary in size, workflow, and environmental requirements. Tailored solutions allow selection of door types, materials, and finishes to align with operational needs. This flexibility ensures that each installation complements its environment, enhancing efficiency while preserving the integrity of the clean room.

Sustainability is increasingly relevant. Selecting materials that are durable, easy to maintain, and environmentally conscious can reduce long-term costs while supporting corporate responsibility. Doors designed with these principles are not only functional but also aligned with modern environmental standards.

Maintenance should be straightforward and predictable. Modular components simplify replacement and repair, minimize downtime, and support continuous operation. Attention to long-term performance ensures that facilities remain compliant with industry regulations without excessive operational burden.

When choosing a clean room door, balancing durability, hygiene, and usability is essential. Sophisticated installations blend technical innovation with practical performance. For those seeking dependable solutions, is your current infrastructure meeting all operational and safety expectations?

To explore complete options and specifications, visit www.yd-purification.com/product/cleanroom-doors/ and learn how your facility can benefit from advanced clean room solutions.